That Glorious Formula 1 Sound….

A quick Google search for “best sounding production car” will undoubtedly yield top hits containing references to the Ferrari F355’s flat plane crank, 8500rpm, cinquevalvole masterpiece, or at least it should. And reality doesn’t disappoint, the sound of this car is truly exhilarating.

The exhaust note of an F355 sounds fantastic. The exhaust note of a F355 with an aftermarket exhaust sounds extraordinary. This is therefore one of the few areas that I felt warrant an “upgrade”, and not just for the sound. A mere 5 minutes of internet research will reveal that the factory exhaust manifolds are a serious point of concern. They appear to have a terrible failure rate, and indeed on my car they were replaced at 21,000 miles (under previous ownership). It is very common for the manifolds to be replaced with aftermarket offerings - sometimes because of actual failure, and many times to simply eliminate the risk and liability of the failure prone factory manifolds. I fall into the latter category, I changed the manifolds preemptively, even though the factory manifolds did not fail (which now have 23,000 miles on them). I must admit that although I take everything I read on the internet with a grain of salt, it did feel that the factory manifolds were a liability, and I wanted to have everything about the car the right “spec”. Even before I bought the car, I knew that I would replace the manifolds at the first convenient opportunity : the engine out service. Fortunately there are several aftermarket offerings, which have been discussed at length on the various forums. In my opinion, the manifolds from Tubi Style are the clear choice. They maintain the 4-2-1 design of the originals, they are very well made, and have a heatsheild that is not only functional, but beautiful; they check all the boxes - but unfortunately they are spendy. Doing all the work myself, I justify the higher cost of the parts by the savings on the labour, which helps me achieve my goal : the “right” configuration car in the best possible condition.

Down stream of the manifolds, I replaced the catalytic converters, and the muffler, as well as replacing or reconditioning all mounting hardware, gaskets and seals. While not technically the exhaust system, there is oil return check valve under the SX manifold, that will really appreciate getting the hoses replaced, as they basically get vulcanized due to heat (I replaced the heatsheild as well) The only things that were not replaced were the Y-Pipe and the bypass valve (which is original and does not rattle). The catalytic converters are Evoflow units, which are very well made, and in fact I asked that they be built in the M2.7 configuration, which means no post cat lambda sensor bung (M2.7 only has pre-cat lambda sensor), just to keep the look a bit cleaner. For the mounting hardware, I generally used the Hill Engineering clamps and bolts where available, copper exhaust nuts on the bolts, as well as flex-top lock nuts for the muffler flanges. I even refurbished the muffler hangers, which includes replacing the spherical bearings (yes, the exhaust hangers have spherical bearings!). The sourcing list of the parts is at the end of this page.

Now to the muffler. I did quite a bit of research on this, and the wide open wail of the Capristo Stage 3 just makes this decision too easy for me. There are a couple of Youtube and Instagram videos of Capristo equipped F355s that I’ve listened to upwards of 100 times that sealed the deal. I felt a bit like Jeremy Clarkson when speaking about the F355, “I have to have it, I just have to!” There are some other very good options (Nuovalari for example), so this all a question of personal taste. We are lucky to have so many good options for our 25 year old cars.

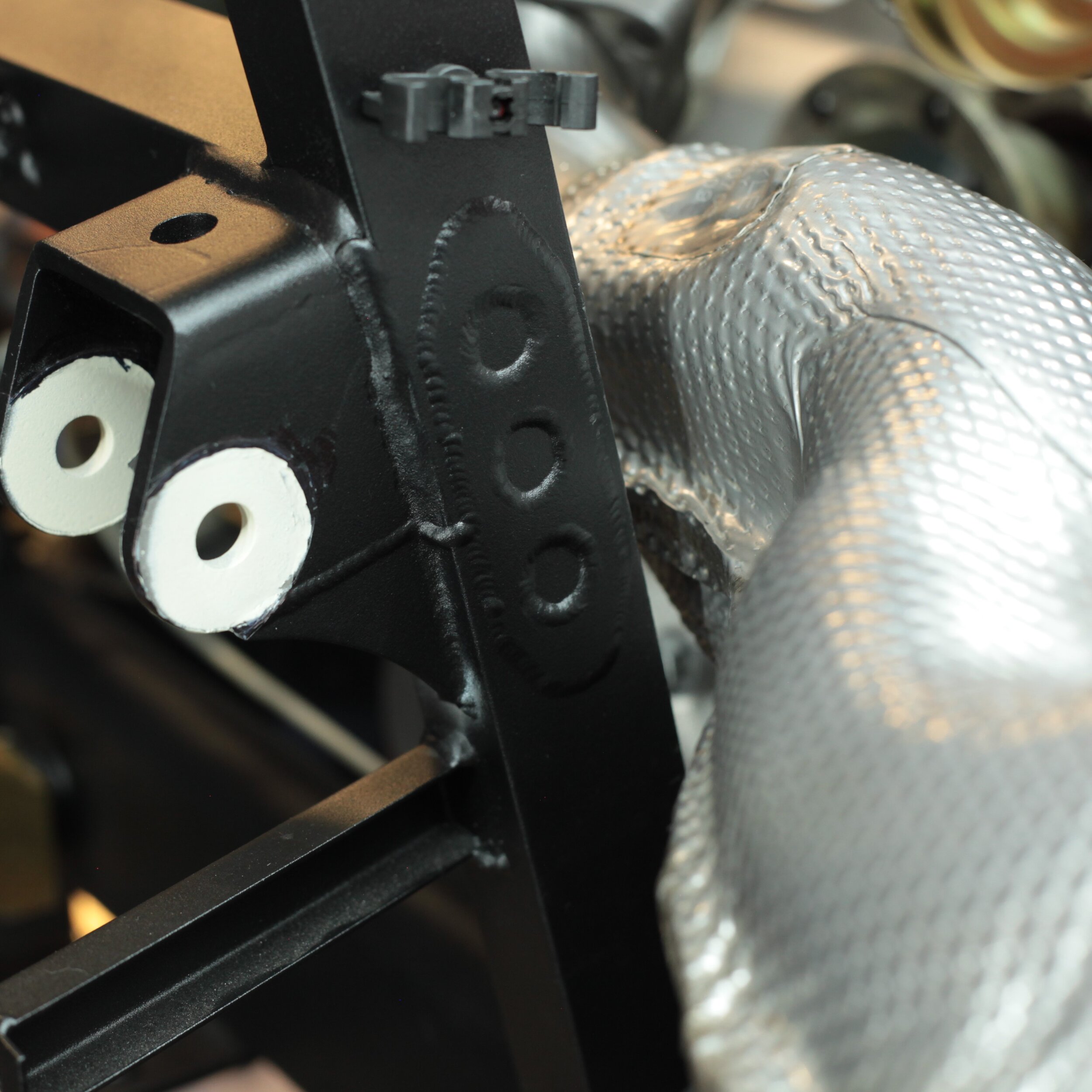

As mentioned earlier I waited to change the exhaust manifolds until I was doing the engine out service, as removal and refitting would be much easier. Nevertheless, it is still tricky to get the Tubi manifolds on when the engine is in the subframe (even if out of the car), as there is marginal (insufficient in my opinion) clearance between the upright of the subframe and the rear most exhaust manifold stud to allow the rear of the manifolds to pass through. Perhaps it is related to the Tubi manifolds having a slightly different heatshield dimension, this I can’t confirm. In any case, I would not be very enthusiatic about taking the manifolds off for whatever reason while the engine is still in the car, due to this interference. In case the situation arises, I made a small modification (I may thank myself in the future for this!); I replaced the rear most manifold stud with one of the same dimension that has an allenkey socket head (it is actually a set screw), in order to allow the removal of the rear stud before the manifolds are removed. This should be a big help because there is not enough exposed thread to be able to get two nuts on the stud (for removal) when the manifolds are installed, and iy is very difficult to get the manifold off the stud due to the interference with the subframe leaving you in a bit of a pickle. Pulling the rear stud out creates sufficient wiggle room to get the manifold of the remaining studs, as well as allowing the manifold to pass through the gap between the cylinder head and the subframe (previously impeded by the rear exhaust stud).

All in all the exhaust system is now, I dare say, perfect. At least to my taste. There isn’t a substandard nut, bolt, or washer, and everything fits together perfectly, and most importantly, it sounds absolutely incredible. And on top of all of this, it legitimately passes the California emissions test.

I left two options listed for the nuts used in the Cat to manifold, and manifold to Y-Pipe joints. I ended up installing the copper slit nut (with nickel anti-seize) instead of the Steel Flex-top locknut. All of the bolted joints have nickel based anti-seize on the threads.